Seno

Imagio

To reduce unnecessary breast biopsies, Seno Medical Instruments, Inc. developed Opto-Acoustic Imaging, a diagnostic technology that distinguishes malignant and benign tissue more accurately than others. Their system combines laser and ultrasound imaging in real-time, to produce high-resolution, high-contrast

images of new blood vessels surrounding a malignant tumor. This groundbreaking technology is contained within a complex medical cart, offering several functional benefits for clinicians, service technicians, and patients alike.

Design and Engineering

Seno Medical enlisted Tactile to help with the industrial design and mechanical engineering of their next-generation medical device, Imagio®, which uses their Opto-Acoustic imaging to diagnose breast cancer and in many cases, without a biopsy.

Like many of our clients, Seno Medical has a fully operational engineering department. However, we offer engineering specialty skills that complement any organization interested in bringing new products to life.

Our Design

Process

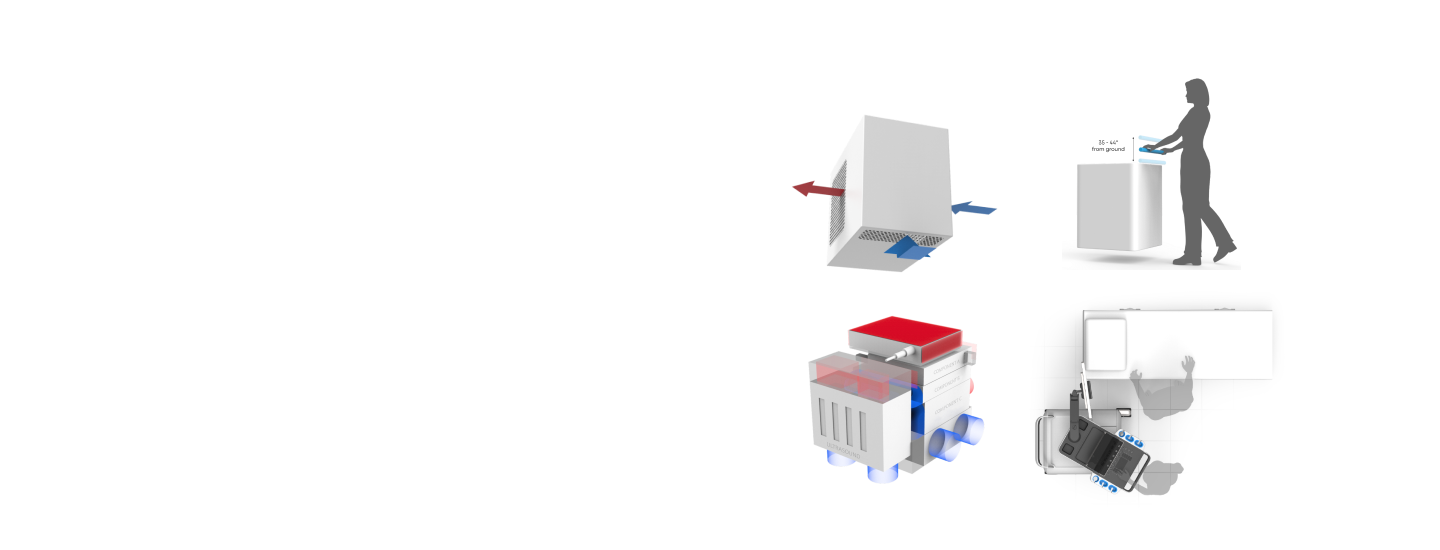

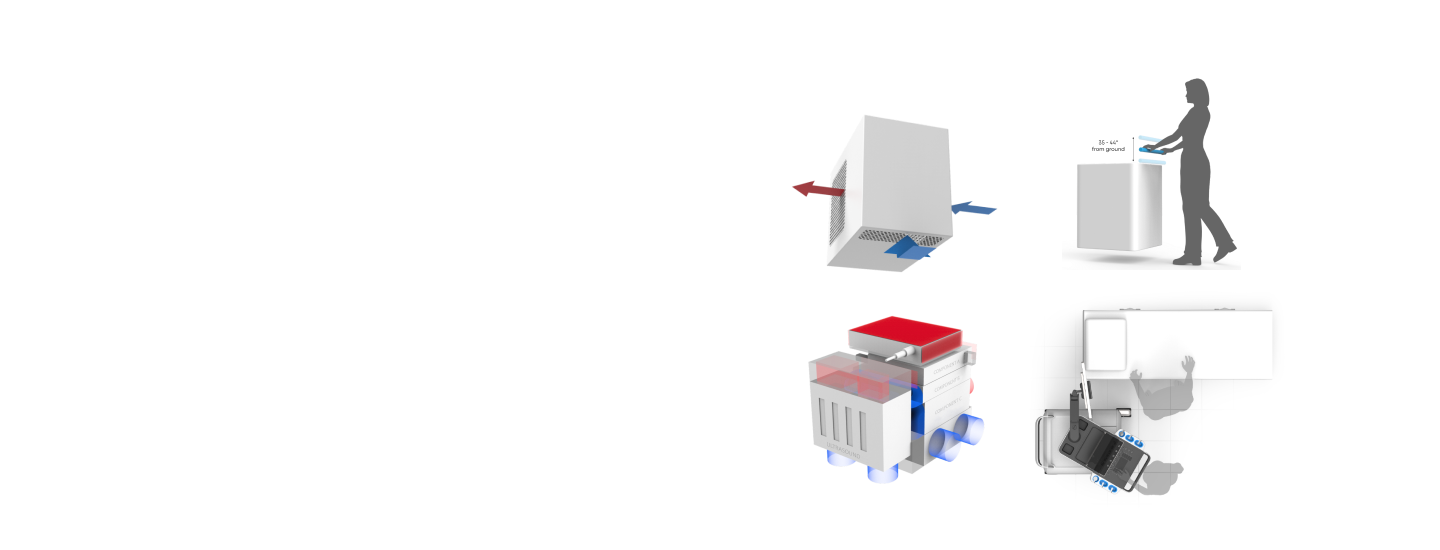

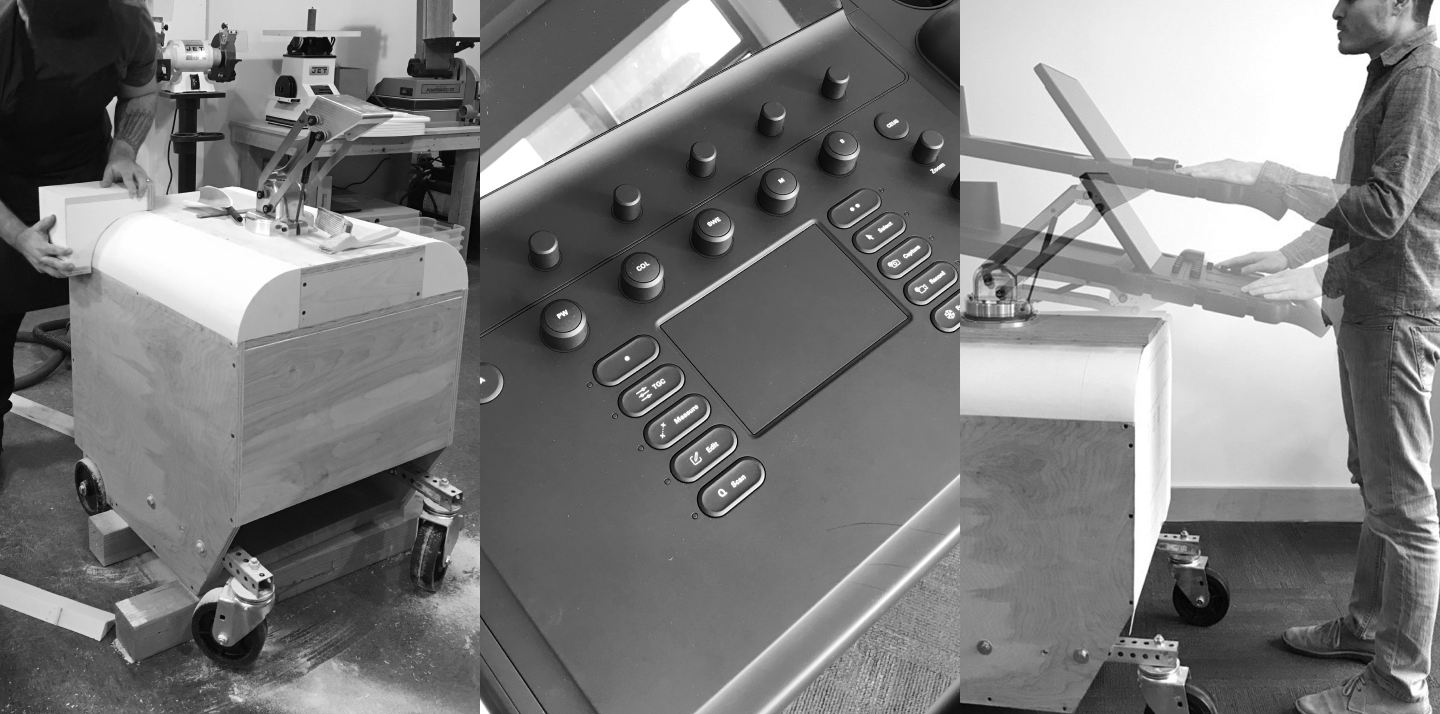

To help Seno Medical to determine critical features of the device functionality, we worked with Seno Medical from the earliest stages of industrial design concept generation, defining volumetrics, end-user interaction, and mechanical engineering architecture.

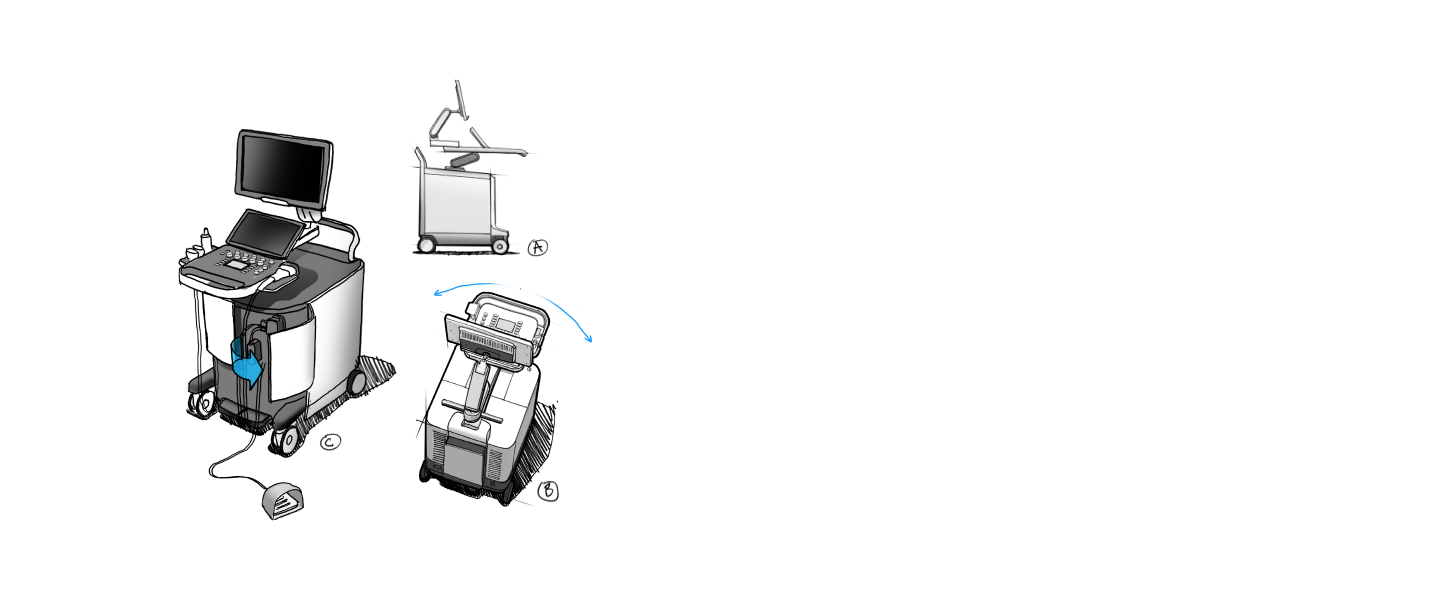

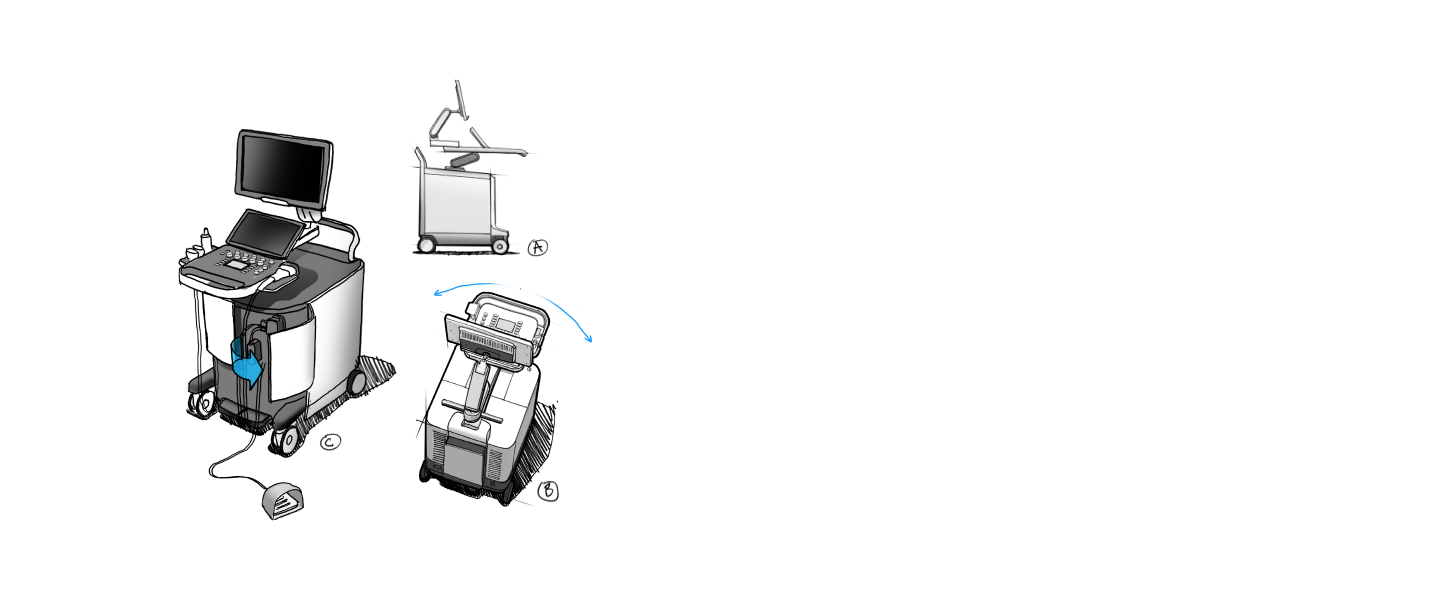

Usability and Architecture Exploration

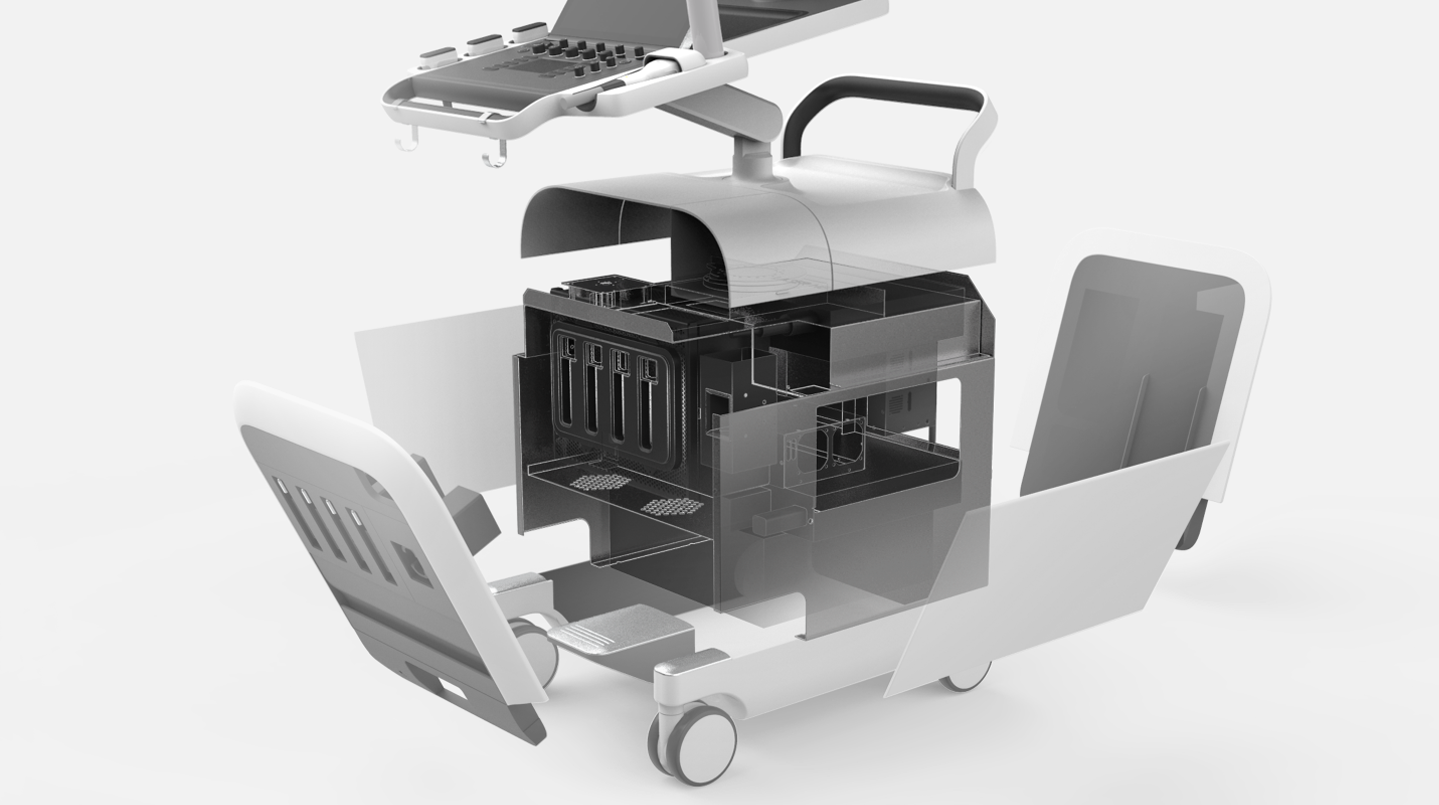

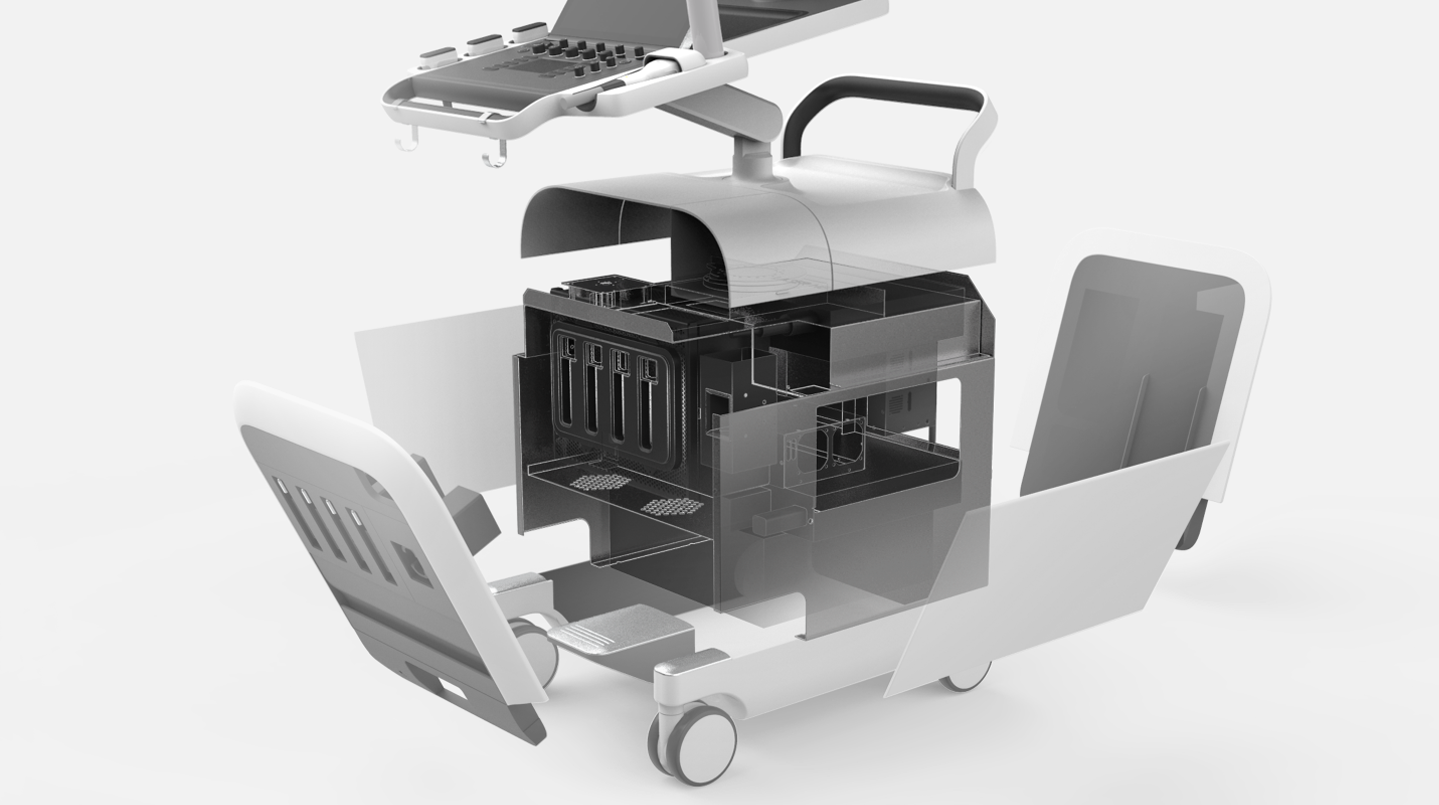

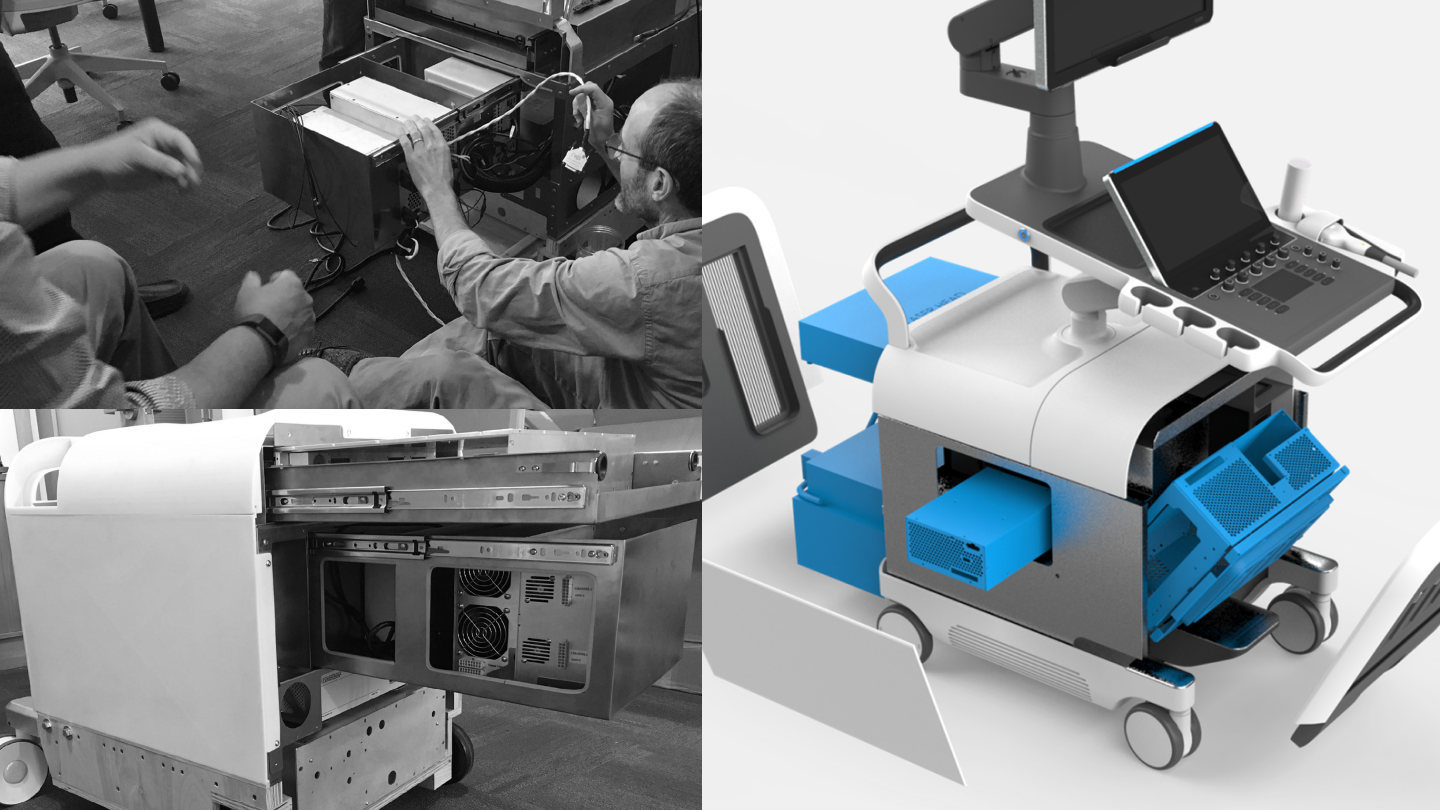

Although Seno’s component technology was established, the arrangement of each part in the cart was up to Tactile’s strategy for space optimization, thermals, accessibility, wire routing, and weight distribution. Usability recommendations included cable management ideas, height guidelines for console use, monitor range of motion, clinic room scenarios, and cart mobility.

Design Concept Exploration

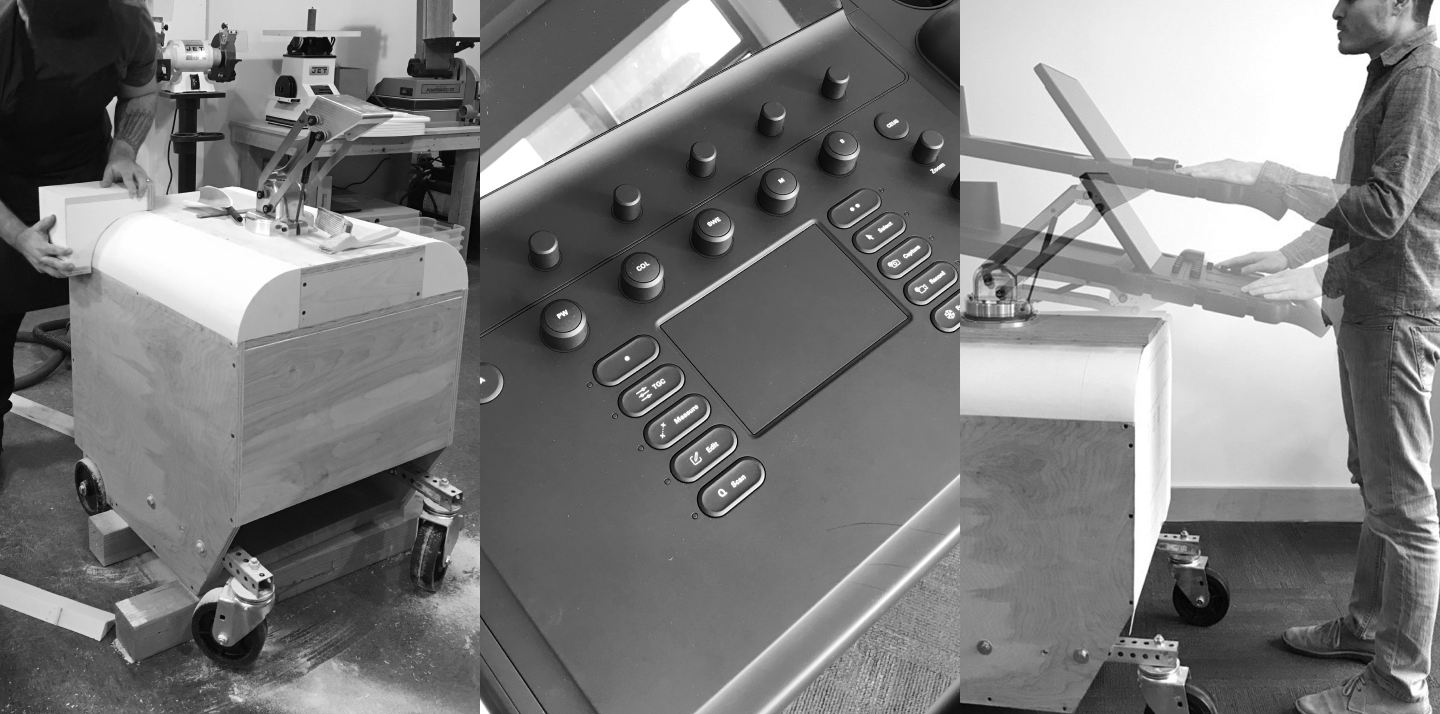

Three design languages were presented to show how they compare product attributes like precision, efficiency, and usability. For instance, the chosen language of chamfers, angles, and exposed ports was best suited for communicating durability, practical functionality, and trustworthiness. Better yet, the design accommodated low-volume production methods like sheet metal and cast parts.

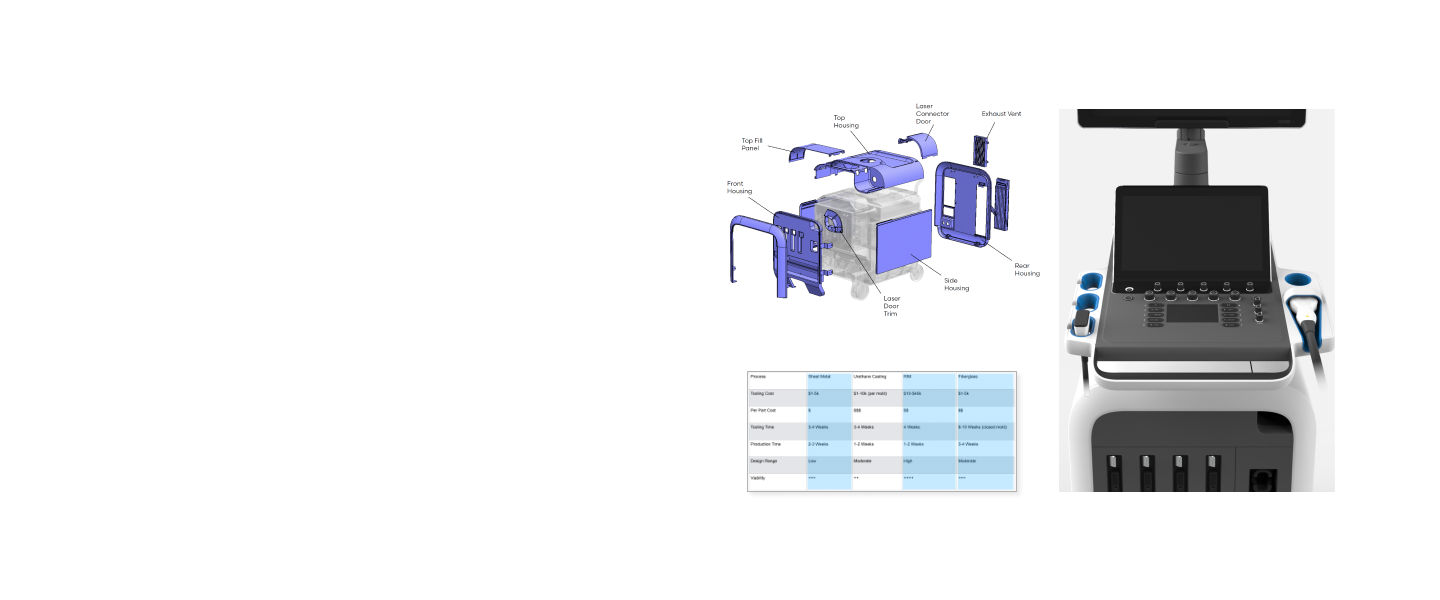

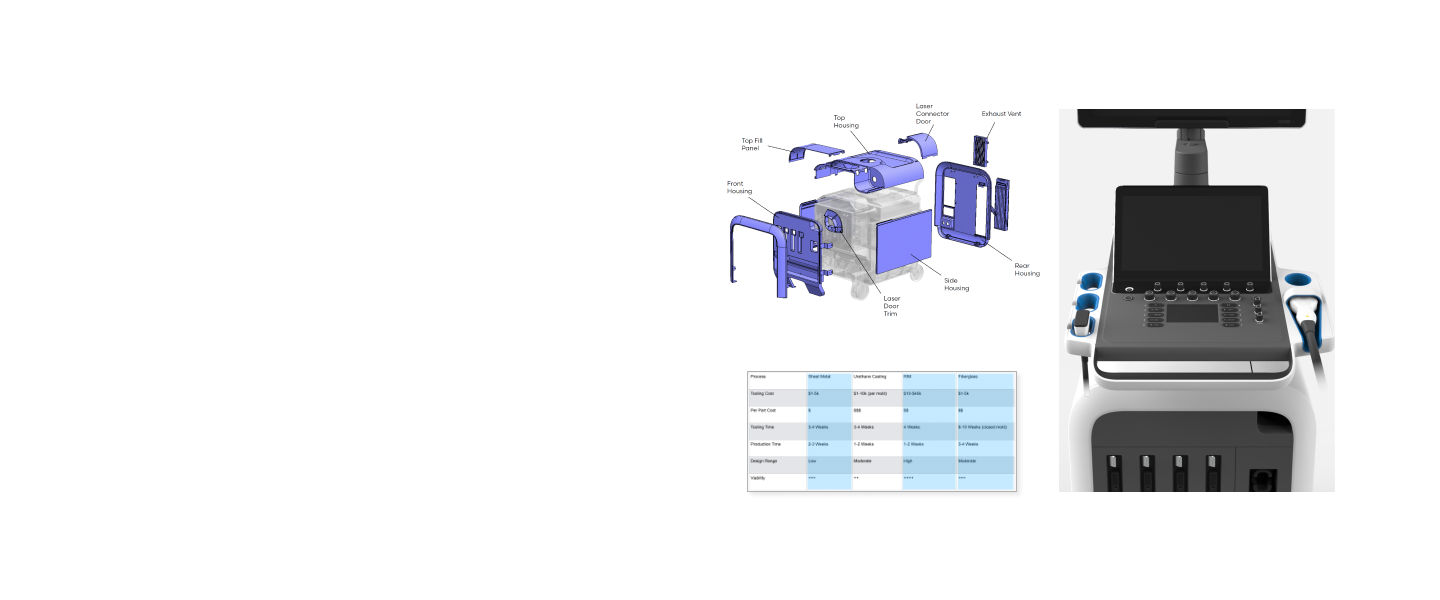

Design Refinement and Engineering

After narrowing on a design direction, details were resolved like console buttons, laser safety storage, cable and plug installation, wheel clearances, filter access and peripheral storage. Colors, finishes, materials, and branding graphics were defined too. This phase initiated engineering efforts of part breakup, manufacturing strategy, serviceability, and technical feasibility for challenges like wheel breaking and armature movement.

Validation

Testing

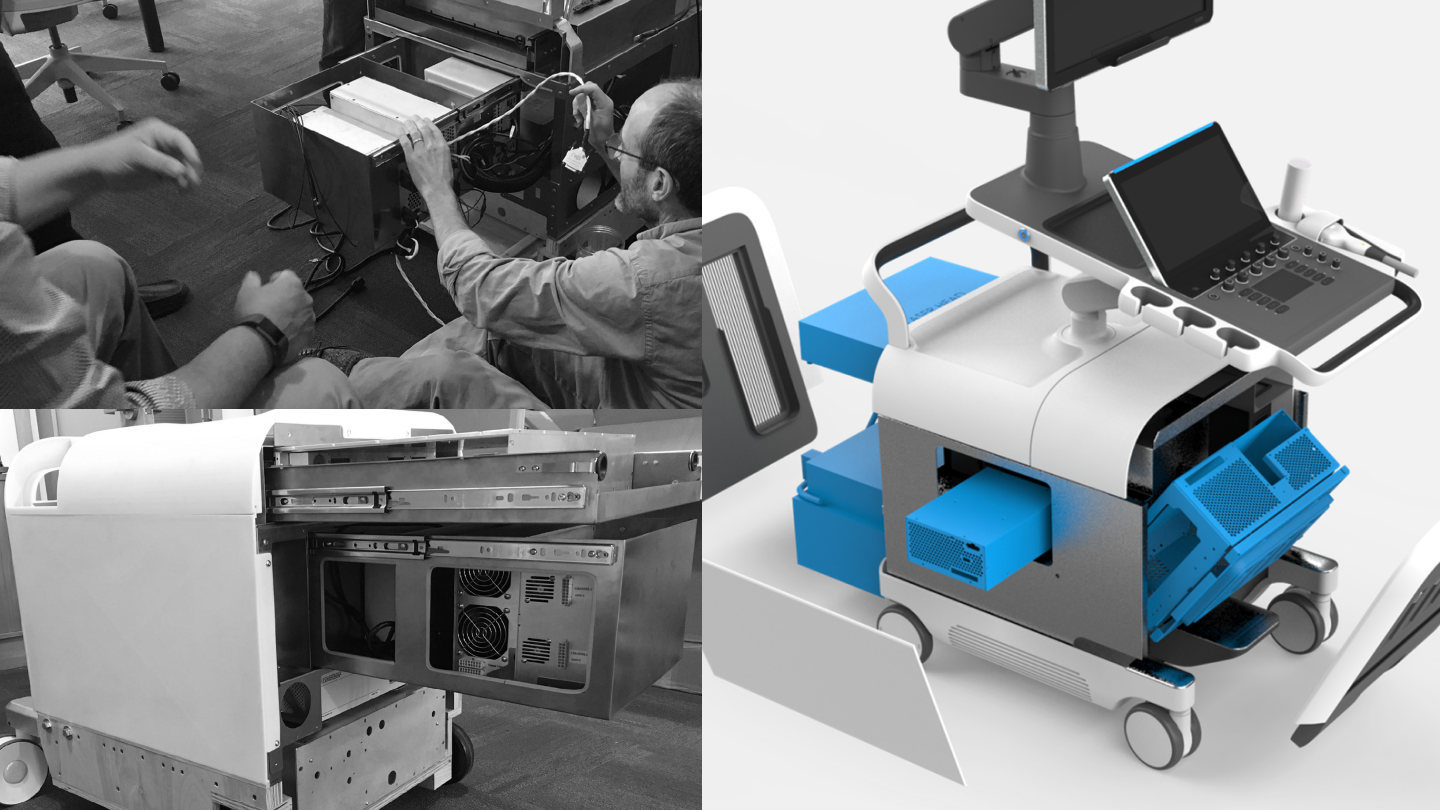

Tactile mechanical engineering specializes in providing the highest quality services from the earliest stages of visualizing a product, building mockups to get a sense of scale, validation, ergonomics, to providing a proof-of-concept (POC) functional prototype.

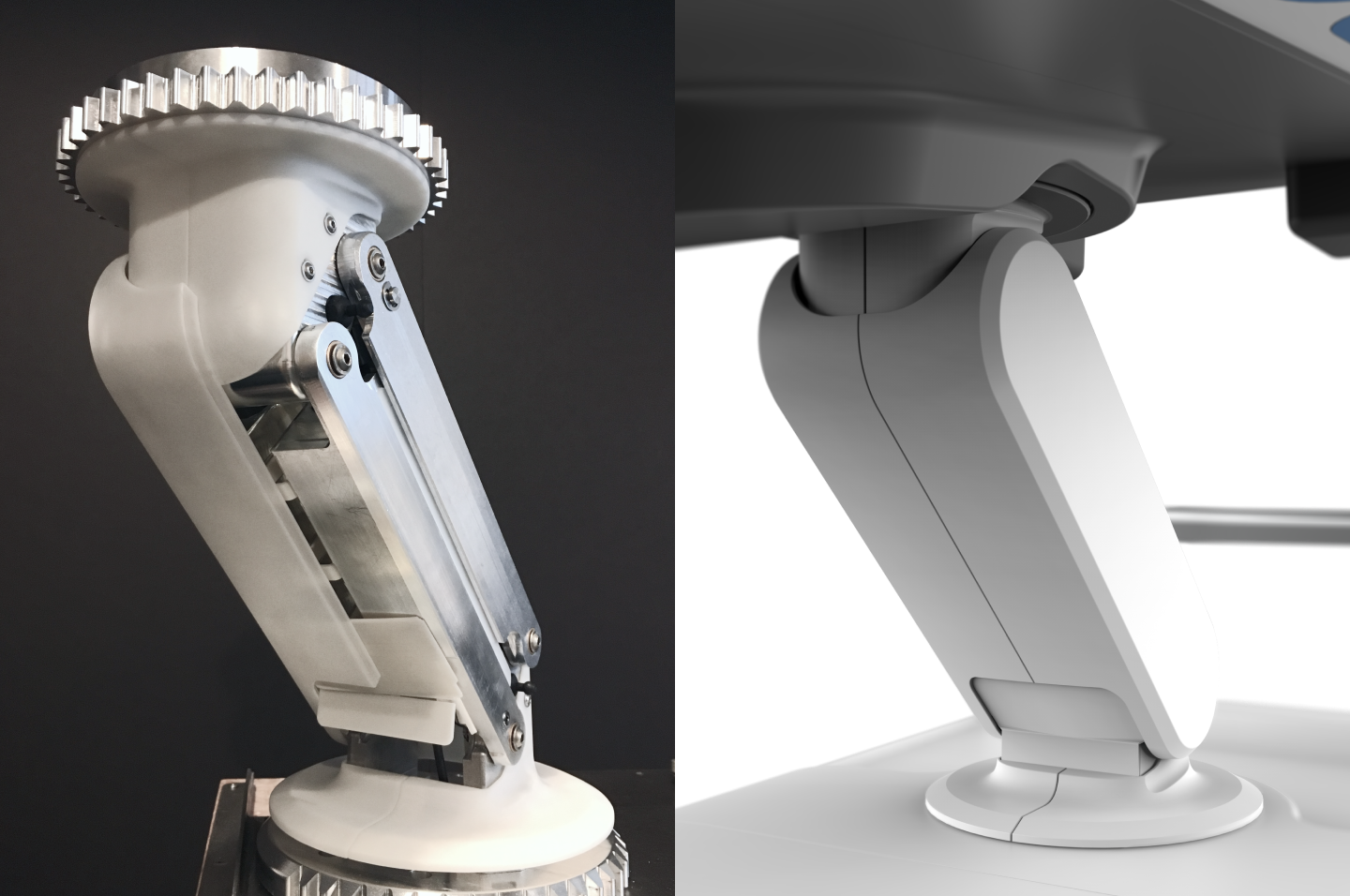

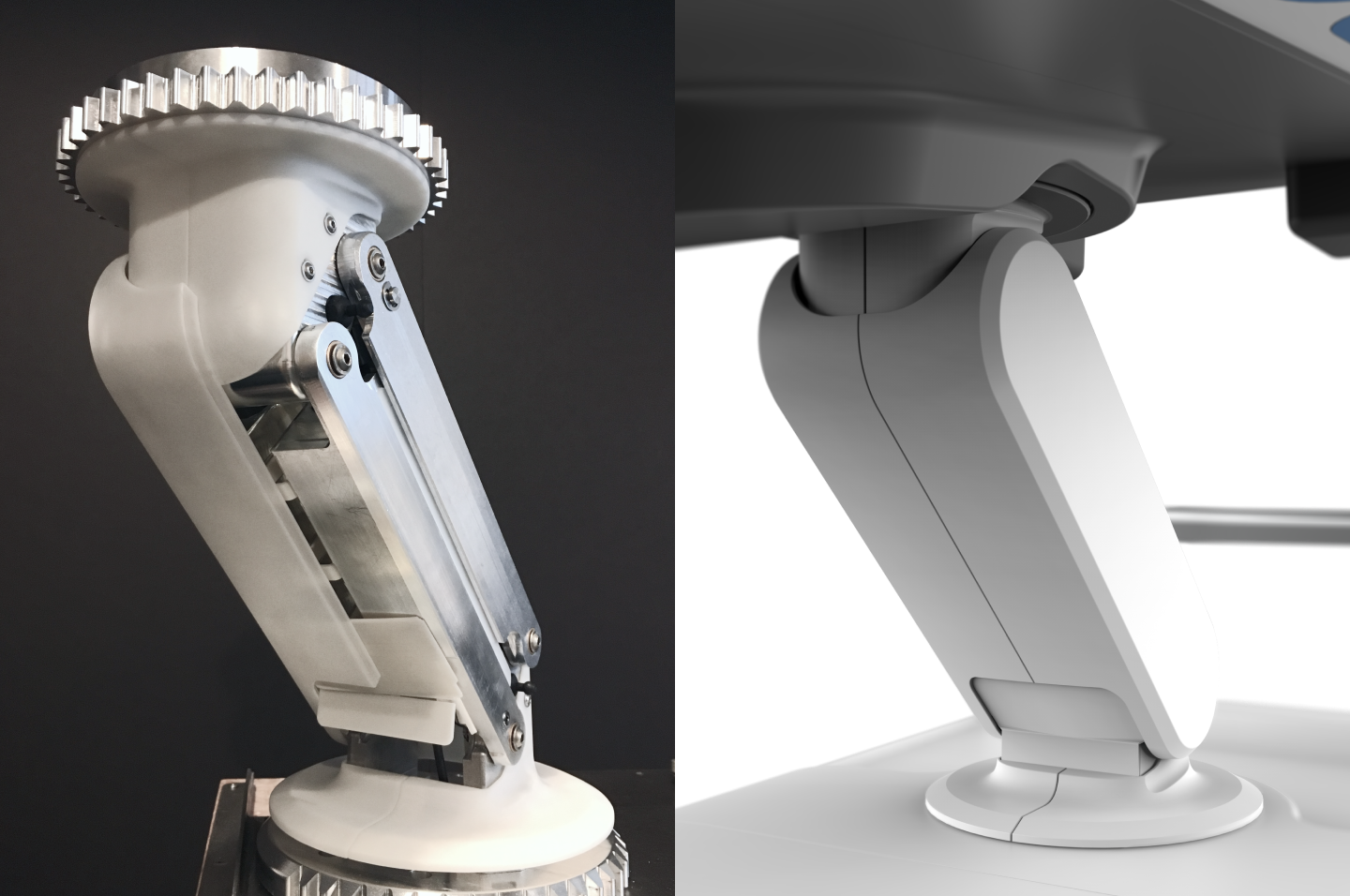

Articulating Armature

Imagio® is a complex medical cart weighing over 400 pounds. Tactile built an articulating armature that’s capable of holding the weight of the user-interface console, positioning the display and user-controls close to the bedside as well as capable of moving the whole cart when locked into position. We explored many options and finalized on a four-bar linkage design with gas-assist for raising the user interface

console. Additionally, low-friction slew bearings were used to allow for two points of rotation both at the cart interface and at the console interface. The armature is locked into position when inactive and electromechanical silinoids are utilized for unlocking the armature in short intervals to move the arm into the desired position.

Thoughtfully

Designed Inside

and Out

Throughout the project, Tactile’s design and engineering teams worked together to ensure that the outcome functioned as well as it looked. Aesthetic details like durable chamfered corners, wipeable surfaces, and intentional feature locations were married with engineering details like precision machined gears, and sliding armature panels that conceal mechanics. Through constant collaboration, the final design remained faithful to the initial concept.

Compact Wheel Lock

A simple and intuitive foot-activated locking mechanism was built for the two front wheels of the cart. This is complicated by the position and wheels out away from the cart. We designed a mechanism,

which mounts to a flat plate for rigidity and takes up very little space while also making the foot-activated lock serviceable in the field.

Clever Component Access

Due to Imagio®’s size, the unit needed to be reliable and easily serviceable on-location by trained technicians. We developed a drawer system for the most frequently serviced internal components. The service technician can remove a few discrete screws on the device along with three body panels, offering direct access to cabling and any diagnostic connections. The compact drawer system allows all the components to be tightly packaged during use

but easily exposed during service. The drawer holds the weight of the heavy components during service and within their cord length so technicians don’t have the burden of lifting heavy loads, balancing components on small surfaces, or disconnecting circuits. This limits the drop risk for components, allowing for quicker re-assembly and permits diagnostic testing with the device in a partially assembled state.

Supportive Partners

The final deliverable was a functional POC prototype of the entire system, engineering validation unit, design files, and engineering specifications for many of the custom components of the system. We provided design and engineering specification documents that equip Seno Medical engineering to

bring the device to market. We take pride in being able to work alongside companies at any design stage they’re in to support their efforts toward definition, development, and realization of a new product.