Proprio

Paradigm™

Today’s surgeons rely on a mix of legacy tools and technologies that compromise surgeries requiring precision, efficiency, and safety. Proprio is a med-tech company that seeks to improve surgeries through immersive, intelligent technologies. Paradigm️ is their first platform that revolutionizes surgical

performance using multi-modal image registration and light field technology to provide virtual and mixed-reality displays. Tactile-led hardware design and engineering collaboration on the entire system help put this technology in a product suitable for operating rooms.

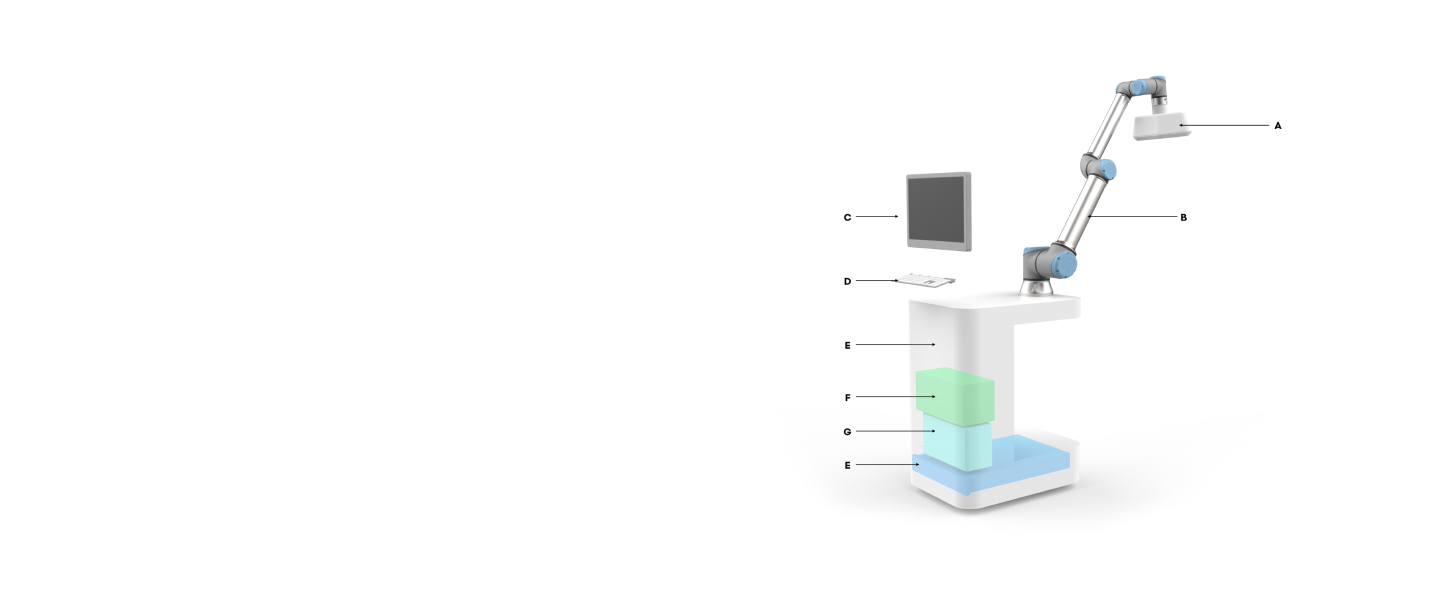

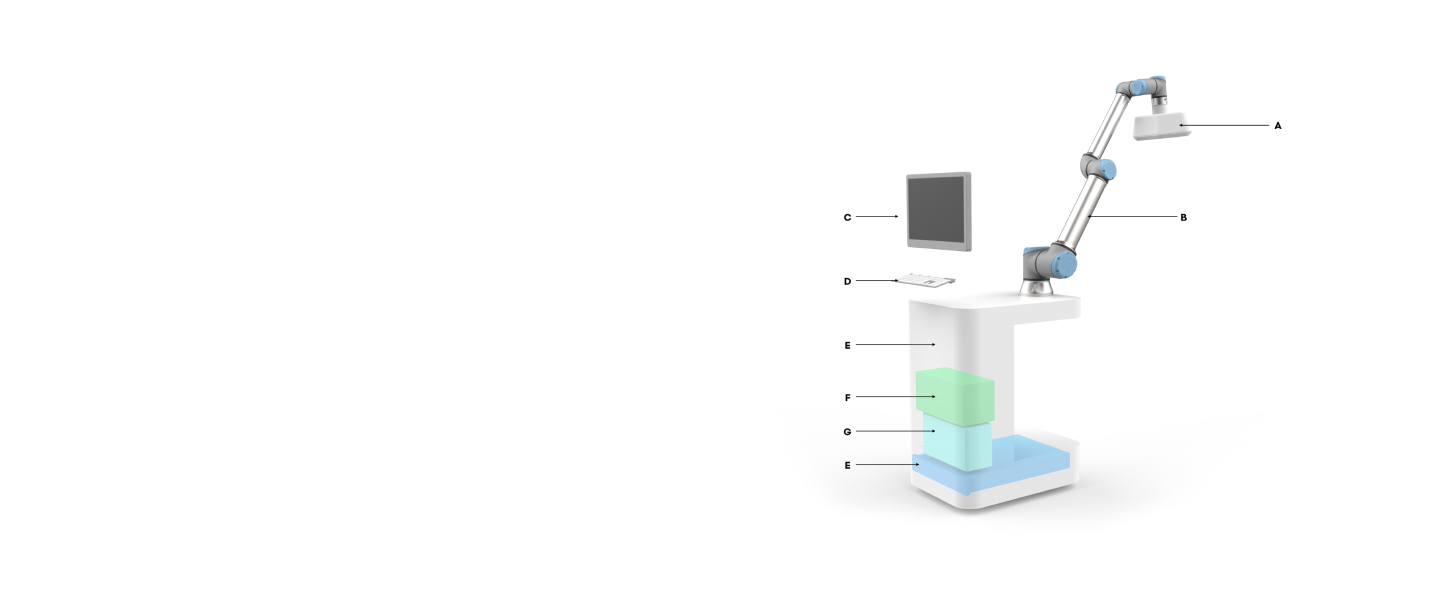

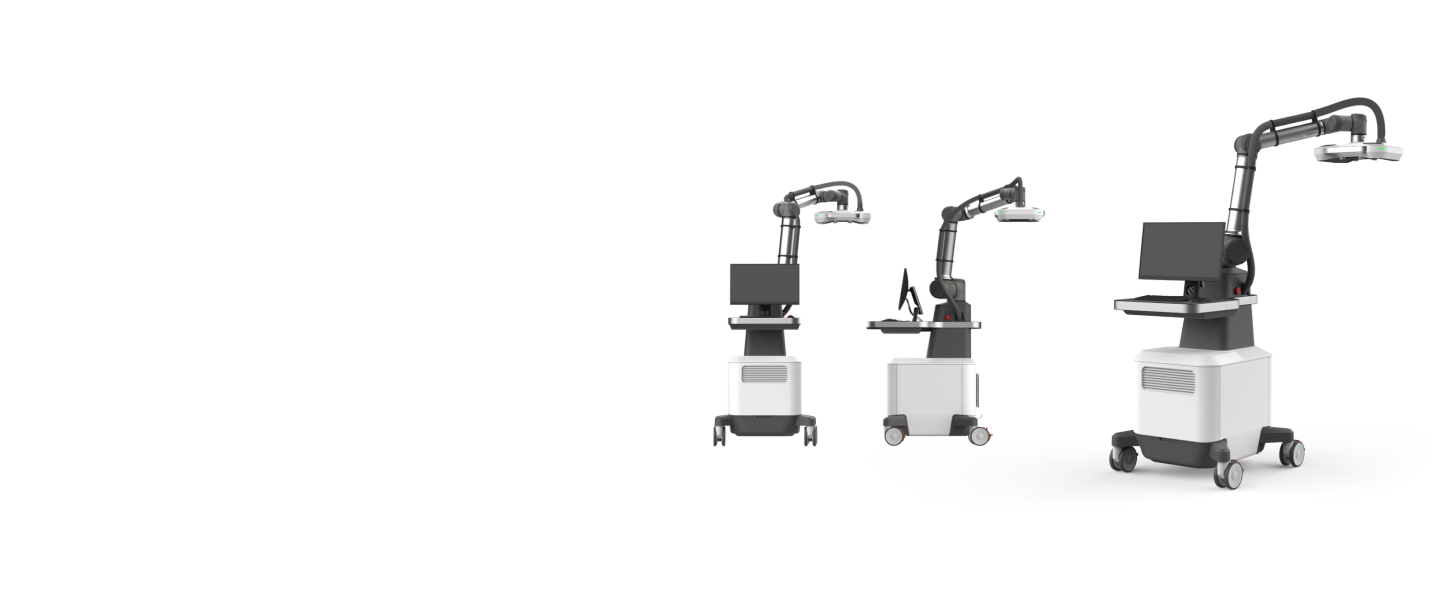

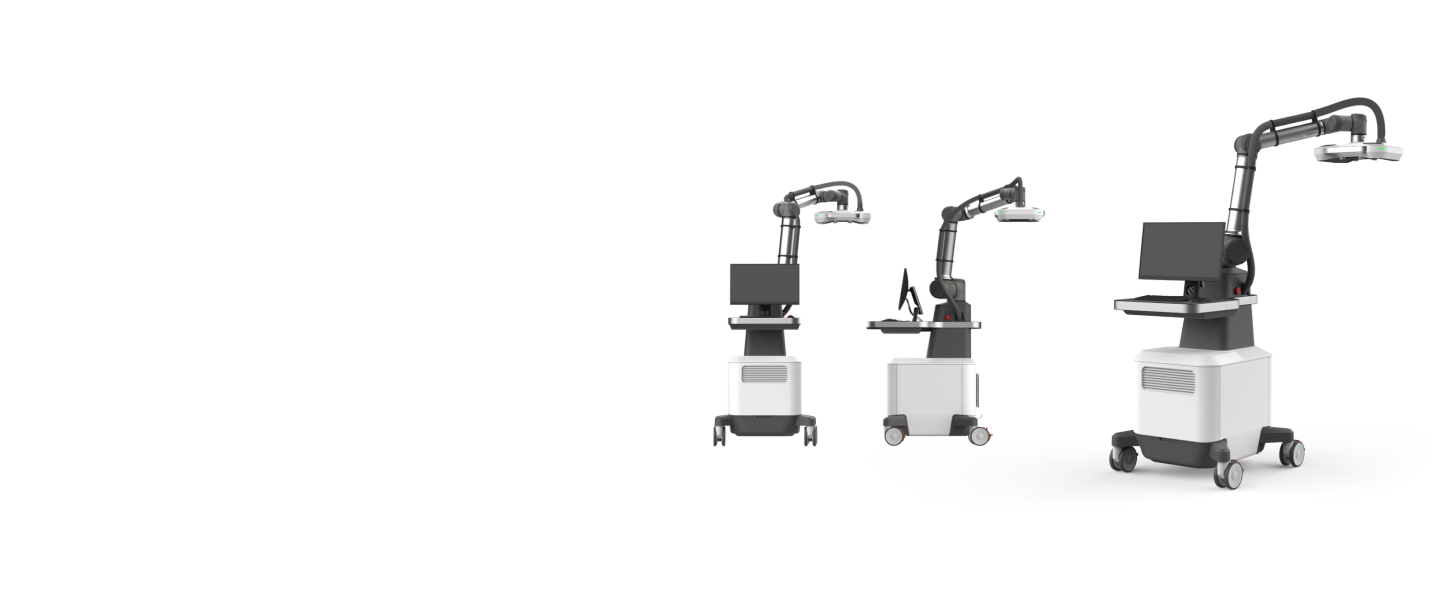

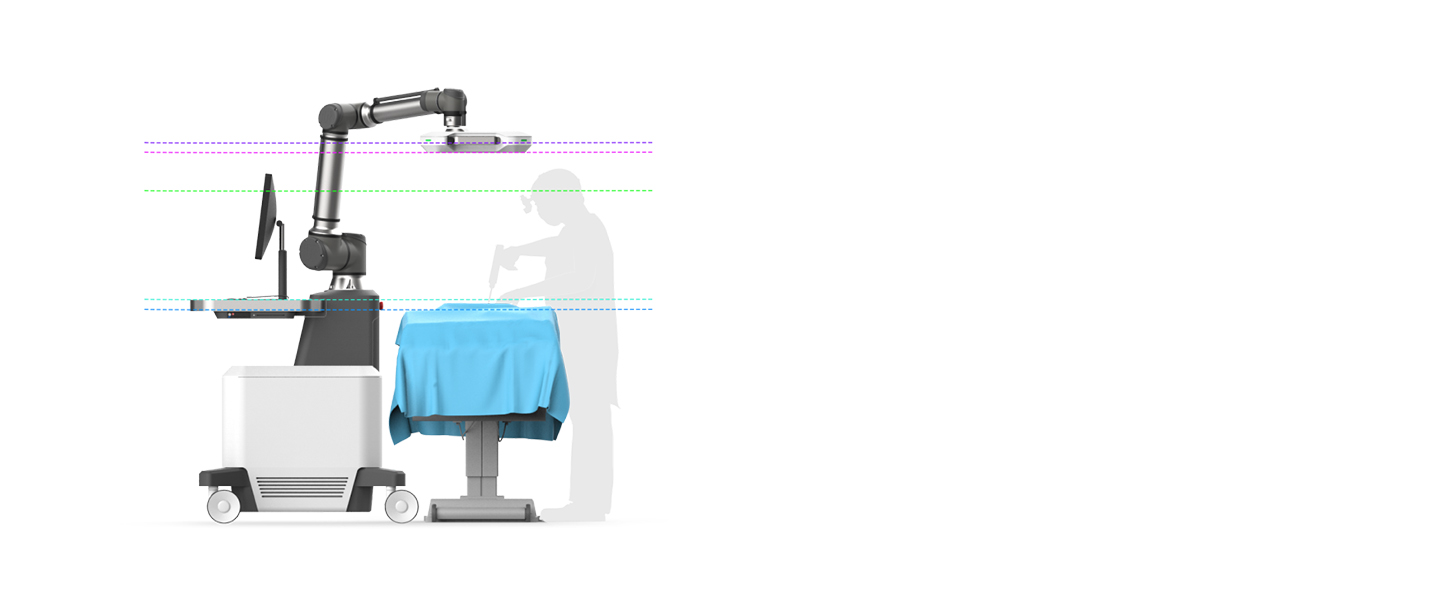

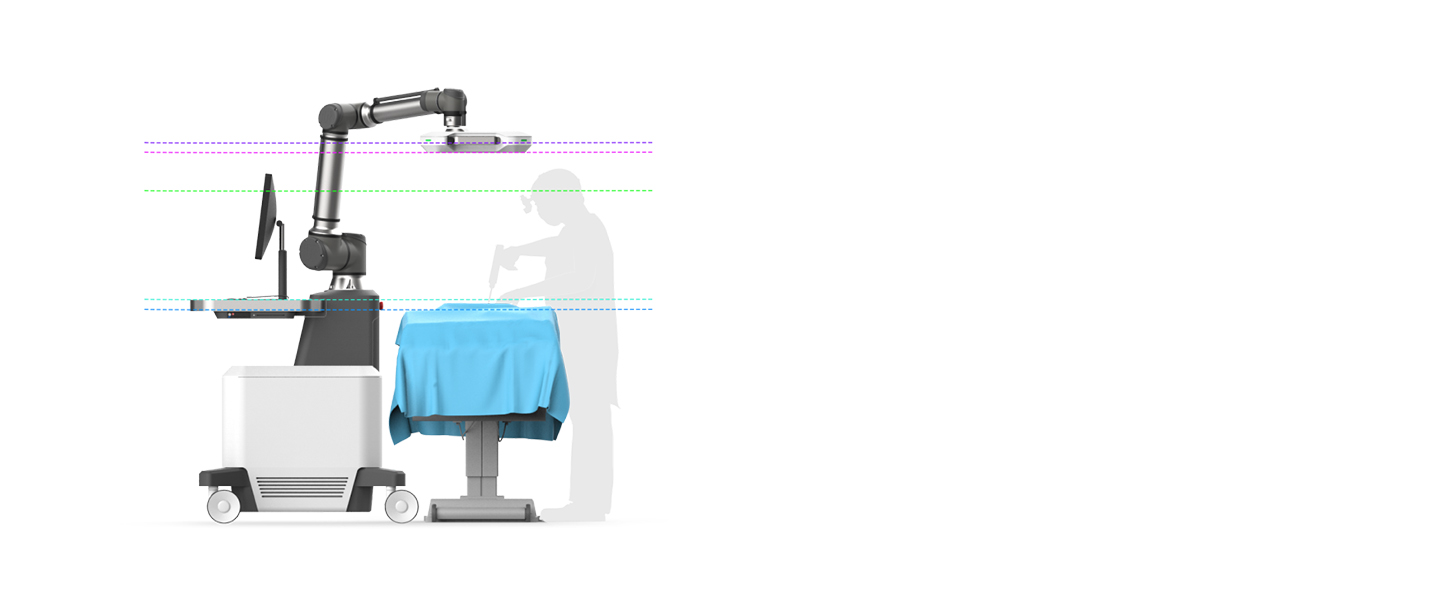

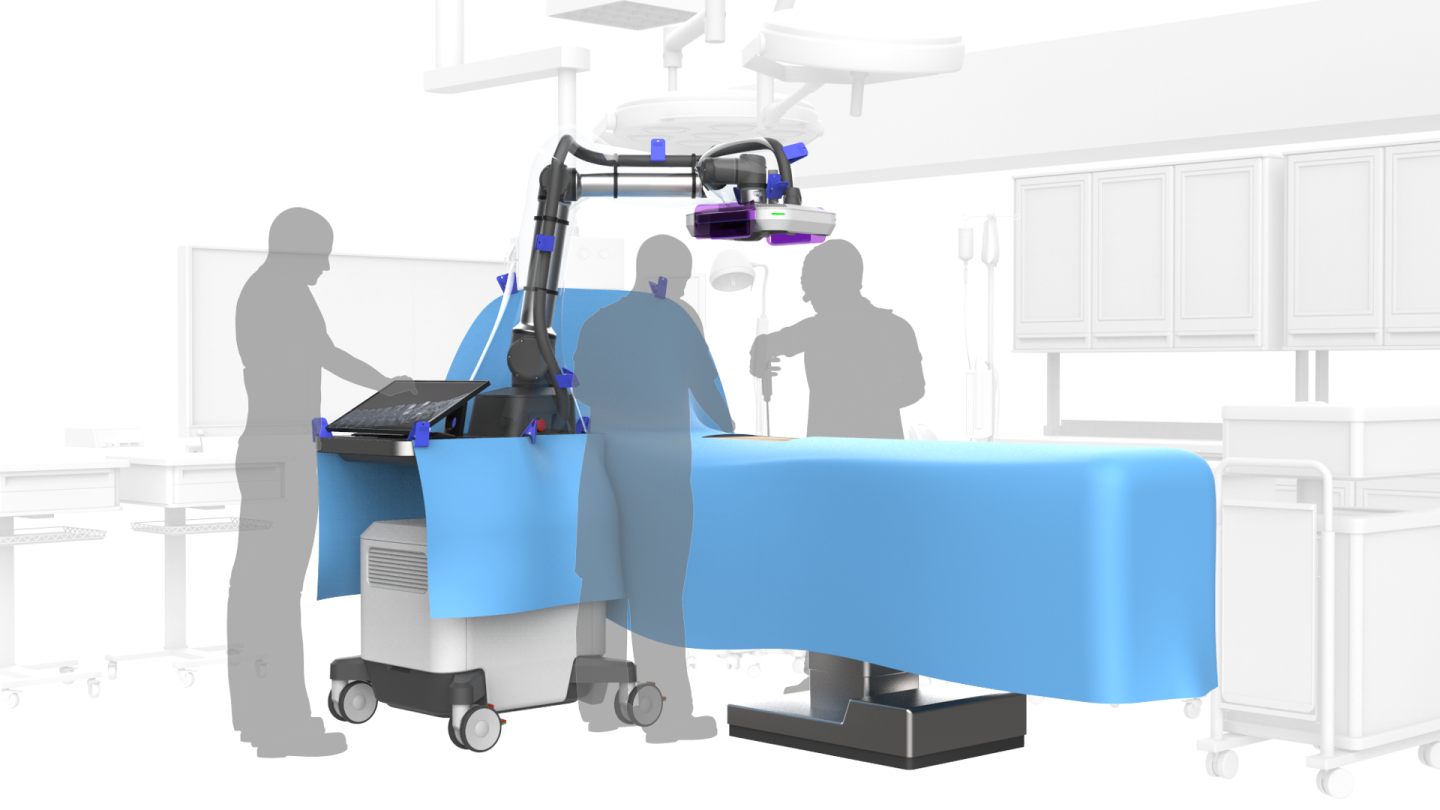

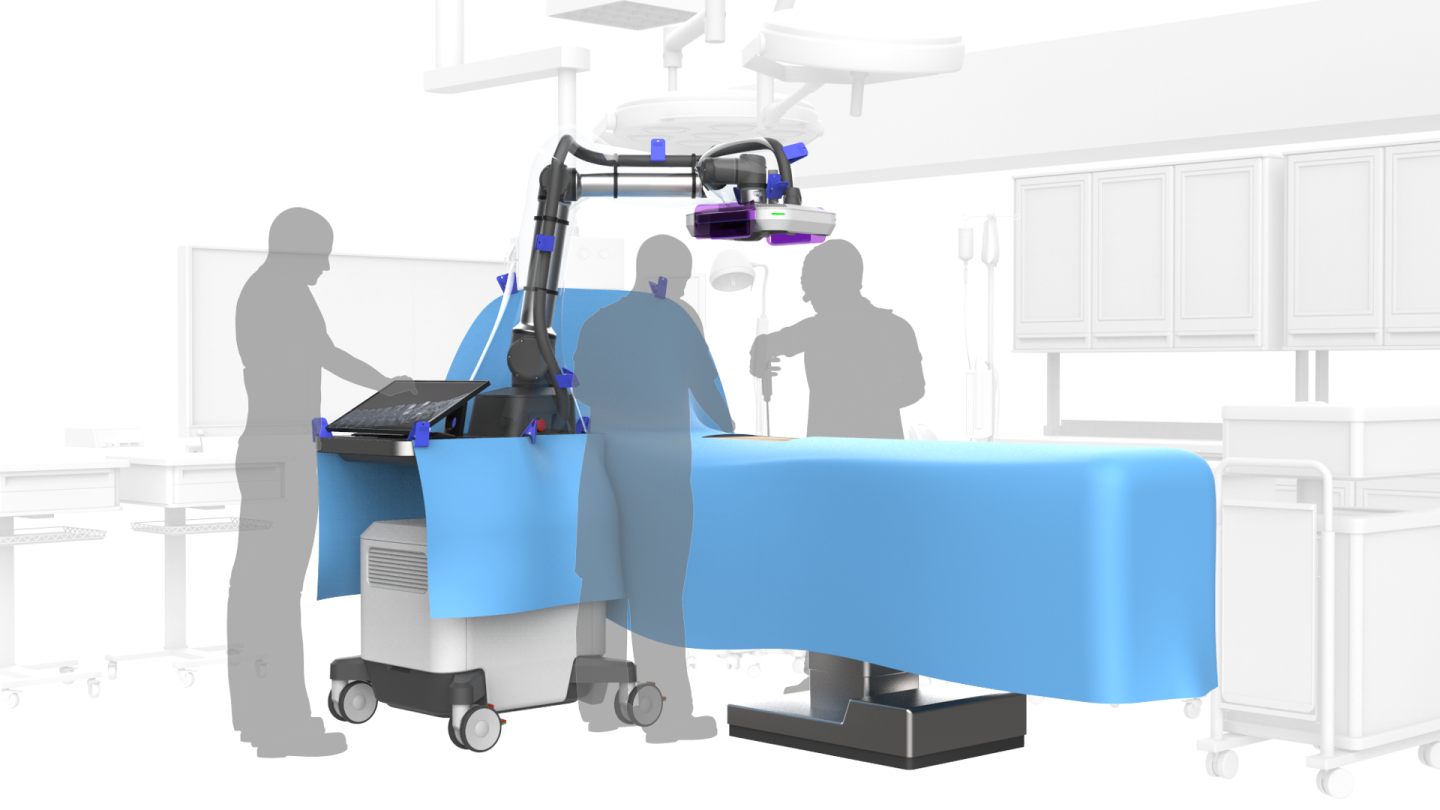

System Hardware Components

The hardware centered at the core of Paradigm️’s platform is Prism™, an array of image sensors, 3D scanning equipment, and video cameras held by a robotic arm positioned above the sterile field in an operating room. The robotic arm extends from a medical cart containing the computer, driver, power,

and interface components powering Proprio’s Adaptive Registration. An integrated workstation table and display provide pre-operative and intraoperative utility, while standalone monitors assist surgeons with critical 3D imagery mapped in real-time to the patient’s anatomy.

Function First

At the onset of this project, our design process was driven by functional opportunities to optimize use in the operating room. We advised component architecture, user scenarios, and environmental

contexts. Getting these fundamentals defined at the beginning of our process gave the proceeding design effort clarity and confidence for Proprio.

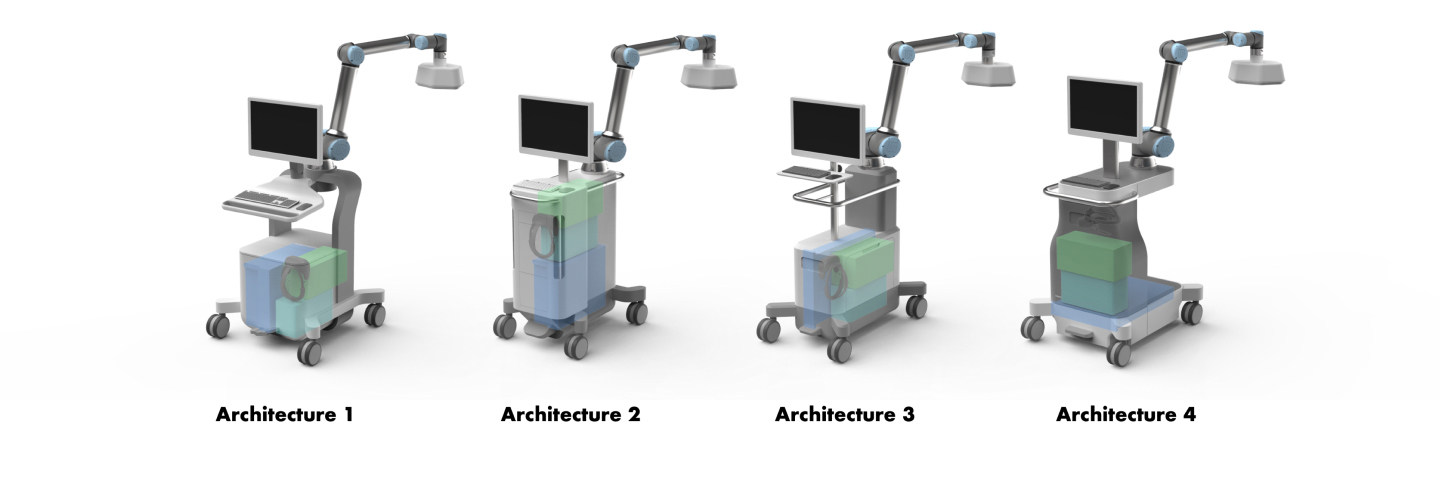

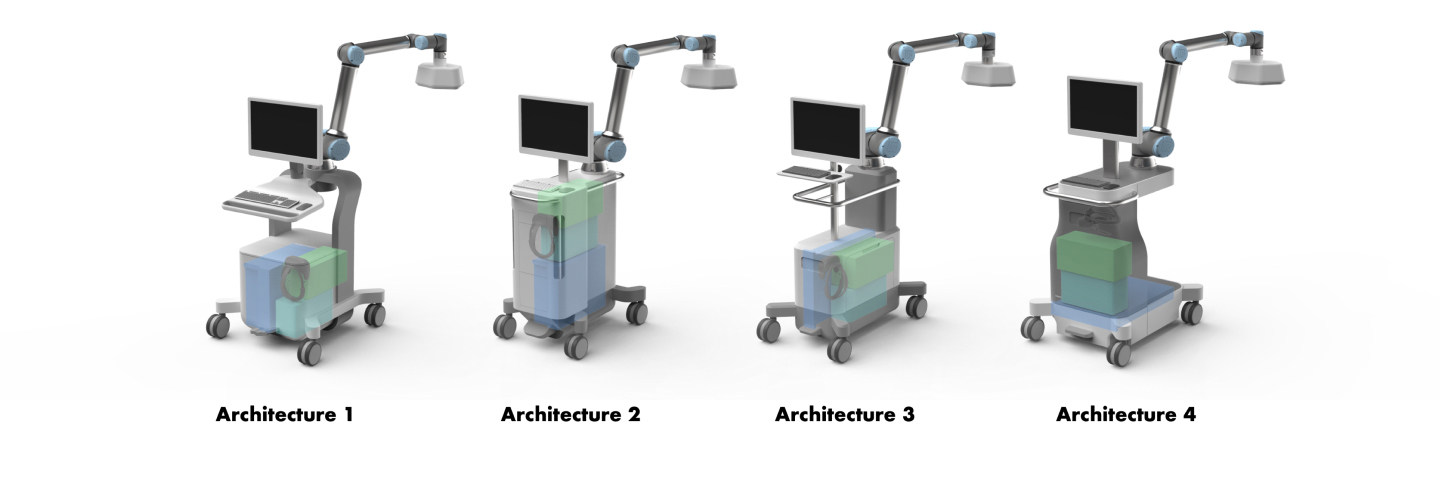

Volumetrics and Architecture

Component architecture concepts evaluated stability, camera reach, integration with the OR table, ergonomics, workstation use, and storage configurations. Each option resulted in a unique volume which informed form exploration and suitability in the operating room.

Form Exploration

Forms were brainstormed with sketches inspired by brand guided themes such as advancement, seamlessness, accuracy, and precision. These qualities were paired with functional attributes like cleanability, durability, adaptability, and serviceability.

Concept Refinement

With greater resolution at each step of the design process, we defined details like robotic arm integration, workstation deck, part breakup, venting, cable ports, E-stop location, storage, cable locations, and handles.

Ergonomics

A critical dimension to determine was the minimum base height of the robotic arm, which extends the 3D sensors above the patient. We used ANSUR data to approximate ideal operating heights which informed camera array height. Arm reach and mount height were plotted for users of various percentiles.

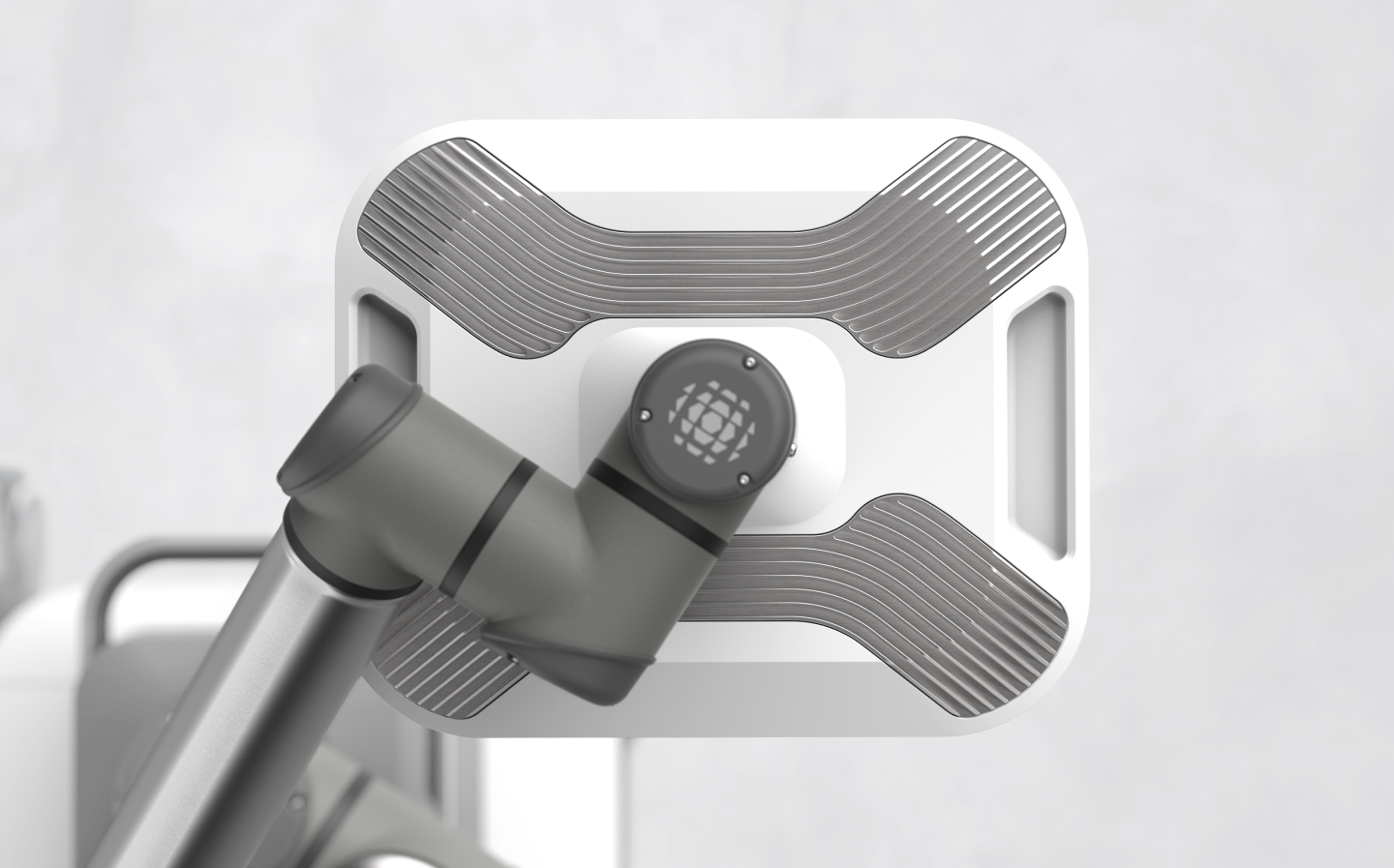

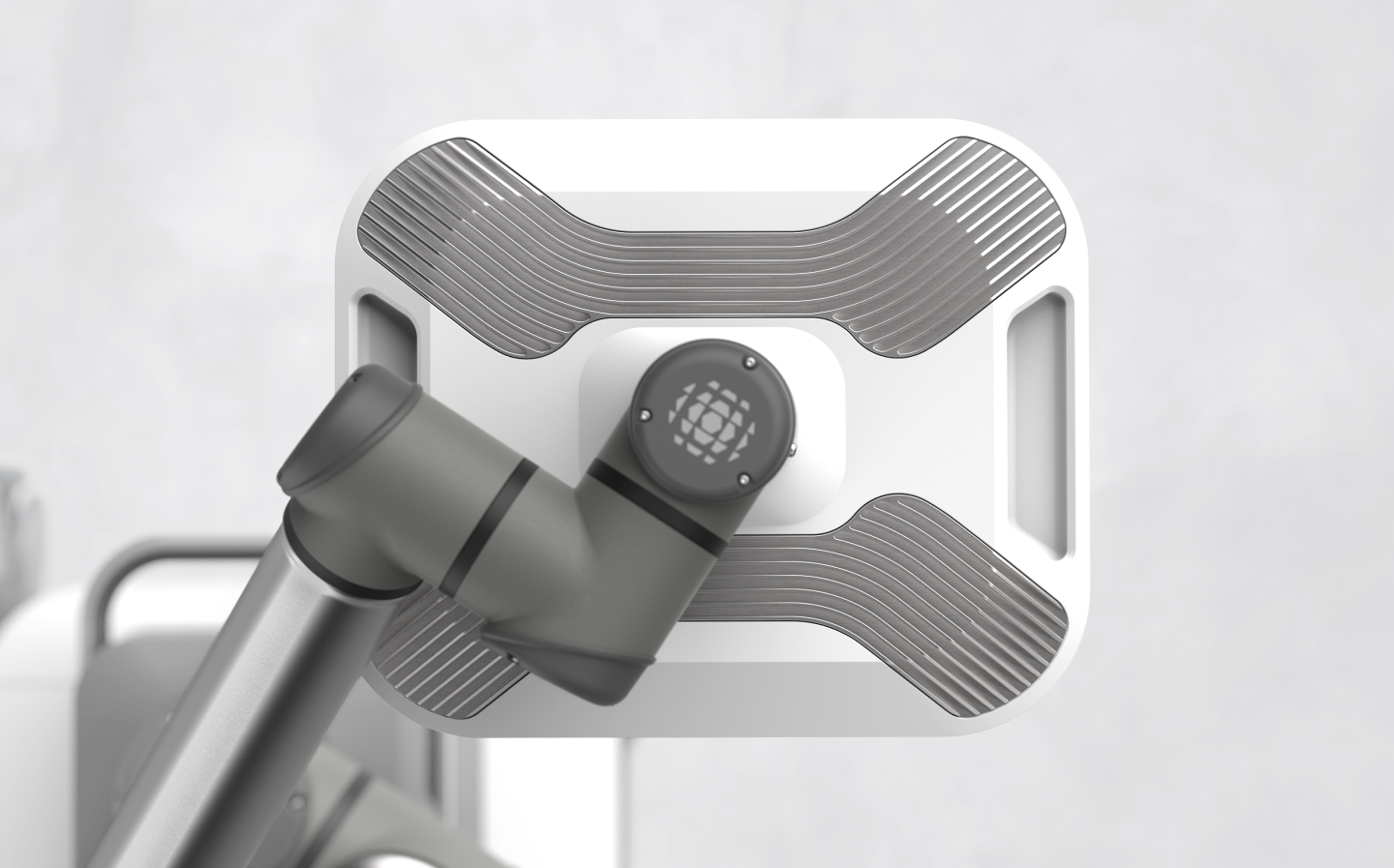

Expressive Thermal Management

Heat produced by the optical sensors required cooling, provided by exposed heat sink fins. This part was machined from solid metal and detailed with flowing lines to accentuate the design and express its

advanced scanning technology. Furthermore, the cart’s venting repeated this expressive approach with a visual metaphor of intaking breaths.

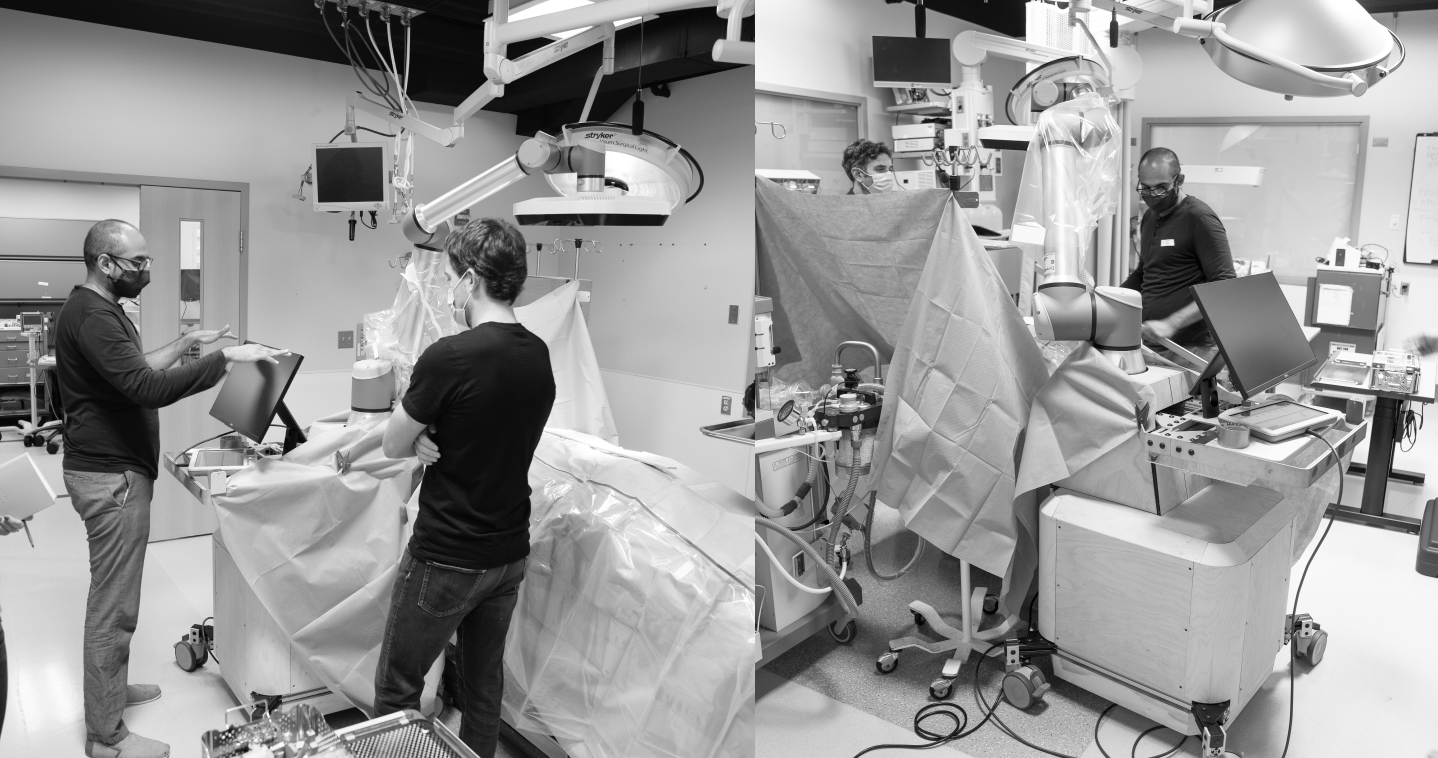

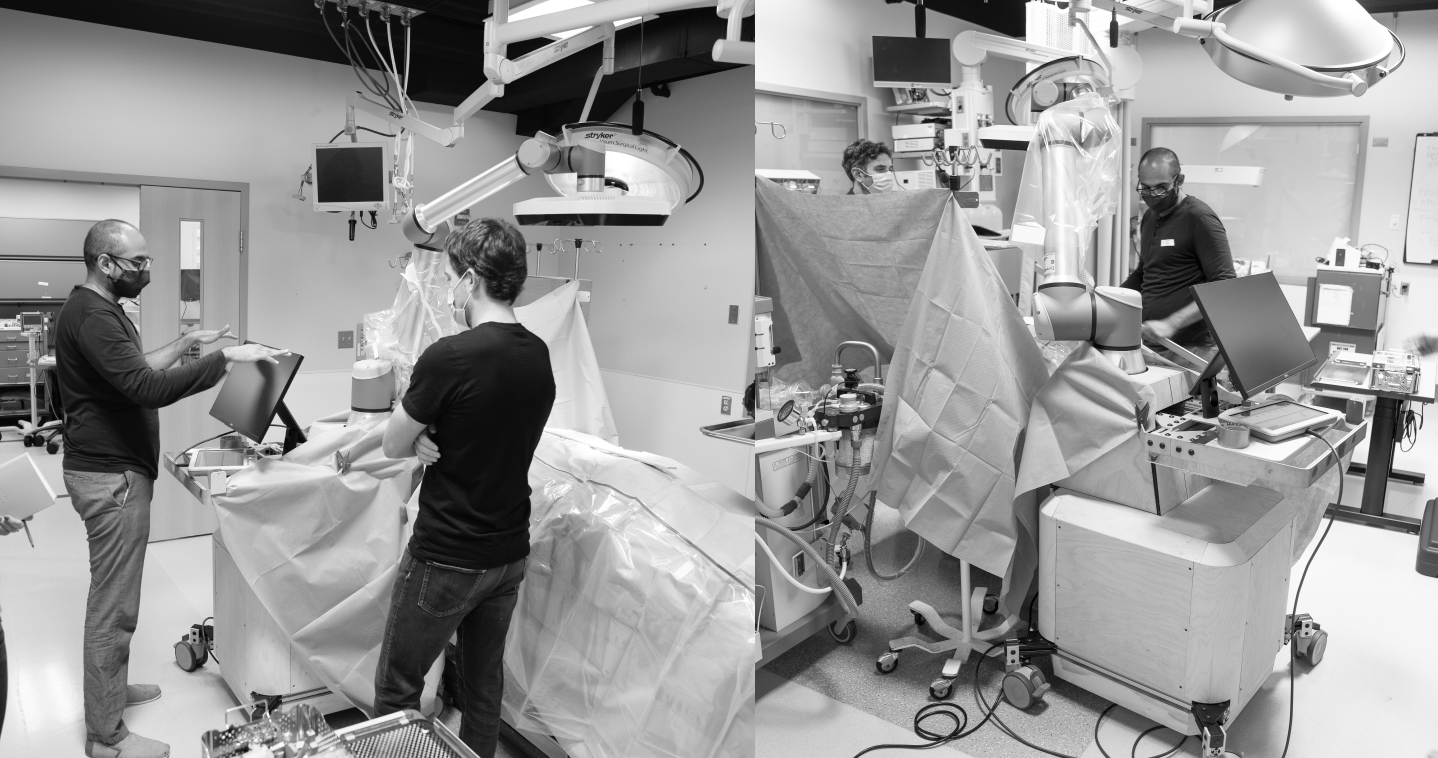

The Value of Prototyping

Full-scale models are the only way to confidently validate a concept. After defining the principle design, we prototyped our ideas to test out assumptions and discover new insights. The proof-of-concept model was built to easily swap components throughout the process based on findings. For instance, the rear I/O panel was updated to test different plug-ins, spacings, and angles. The 3D printed camera array housings were interchangeable and multiple monitors were sourced.

The fidelity of our physical mockup blended a mix of design intent and material practicality to make sure it conveyed important attributes of volume and ergonomics, while ignoring unimportant details like color and material that would add unnecessary time and cost. We deliberately included certain design details like the large radiused corners and the wrap-around handle because they impacted perceived volume and unification of form.

The Future of Medical Technology

The Proprio Paradigm system exemplifies a vision for improving people’s lives through better medical technology. It belongs in a surgical ecosystem designed for the best assistance to surgeons, OR staff,

and hospitals. With Proprio’s proprietary technology and their team of trailblazers, we’re excited to see a future of continued innovation.